it's been a long time again! I was busy with several projects, but nothing is finished yet, so the only thing I could (and probably will) show you are WIPs.

But there's one thing I finished about a month ago and it has to do with casting.

If you ever did cast stuff in resin or plaster, you will surely know what can ruin your day:

Airbubbles!

These are minor and don't catch the eye much, but they actually stress me. One thing I learned from the Hirst-Arts website some time ago is that you can reduce the amount of bubbles by pounding on the table while pouring your cast-medium into the mould. Well the neighbour downstairs will be a lot happier with another solution I picked up somewhere around the web. I made a wacker plate!

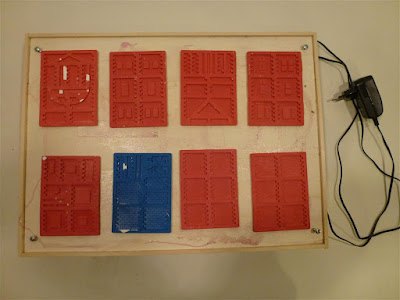

This plate takes up to 8 Linka moulds and leaves enough room between them to cleanly scrape them:

Around the plate I assembled an edging to prevent the moulds from floating of it:

The Screw you can see above fulfills two jobs.

1st: It's kind of a pivot for the spring-suspension of the plate:

2nd: It can be used to carefully level the whole board by

turning it in the threading that was inserted into the wood:

To mount the Spring firmly to the baseplate, you need to make a skew cut into a washer.

This can hold the spring to the base:

So far, so well. This could already do the job. But since we all are kind of lazy,

we can sit back later if we invest a little more time now: Get your solder-irons ready!!

The two round black spots you can see above are the electric motors of two old computer fans.

They both have their casing and fanblades removed and are fixed to the wacker plate.

To create an imbalance, I glued a screw to each motor and coated them with duct-tape.

Just in case it breaks off...

Both fans are connected to a switch and from there to an old 12V power-supply that

I took from a broken network switch.

I'll probably post a video tomorrow to show how it works!

Have a nice day!

Mojo

I would be very interested in seeing how this goes.

ReplyDeletePounding on the table does reduce the bubbles it´s a trick taken from the building industry. Your device looks very interesting

ReplyDeleteVery interesting.

ReplyDeleteHere's another tip to complement your set up: talc or talcum powder. A very fine layer of talc will provide the trapped air with nucleation sites so small bubbles suspended in the solution will conglomerate and float up. It's exactly the same idea as when you place a Mentos tablet inside a carbonated drink.

ReplyDeleteThe ultimate solution is an over pressure chamber, but that is very expensive.

Great and unusual, nice idea!

ReplyDeleteSorry folks, didn't get to do the video yet...

ReplyDeleteHope to get it done during the week!

Hi Mojo,

ReplyDeleteonce again a great turorial.

Therefor I mentioned it on my own blog and dedicated the "Liebster Blog Award" to you.

I hope you enjoy it and have a look here for the rules of the award:

http://montys-caravan.blogspot.de/2012/11/liebster-blog-award-for-montys-caravan.html

Cheers

Monty